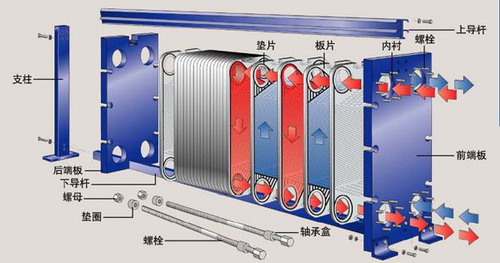

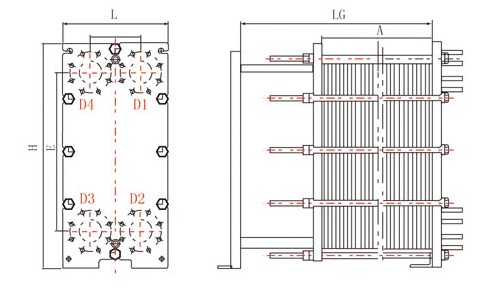

Plate heat exchanger consists of a set of corrugated metal plates, the four corners of the board has holes for both heat transfer fluid through. Sheet metal mounted on a fixed side plate and the pressure plate within the framework of activities and clamped with the clamping bolt. Is equipped with a gasket plate, the fluid channel seal, and guide the fluid to flow alternately to the respective channels, the formation of the heat exchange. Fluid flow, physical properties, pressure drop and temperature difference determines the number and size of plates. Corrugated board not only improves the degree of turbulence, and forming a plurality of support points, to withstand the pressure difference between the media. Metal plate and the pressure plate hanging on activity guides by lower guiding bar, while the rod end is fixed to the support column, due to its high performance, space saving, energy saving, easy maintenance, and many other advantages, plate heat exchanger device has been highly appreciated by the industry. Our products are widely used in metallurgy, food, light industry, chemical industry, refrigeration and HVAC and other fields.

Press Plate material for comparison table

| Sheet materials | Suitable fluid |

| SUS304,316 |

Water, river water, edible oil, mineral oil |

| Ti,ti-Pd | Sea water, salt water, and chloride |

| 20Cr,18Ni,6Mo(254SMO) | Sulfuric acid, sparse salt aqueous solution, an aqueous solution of inorganic |

| Ni | High temperature, high concentration caustic soda |

| HASTELLOY (C276,D205,B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |

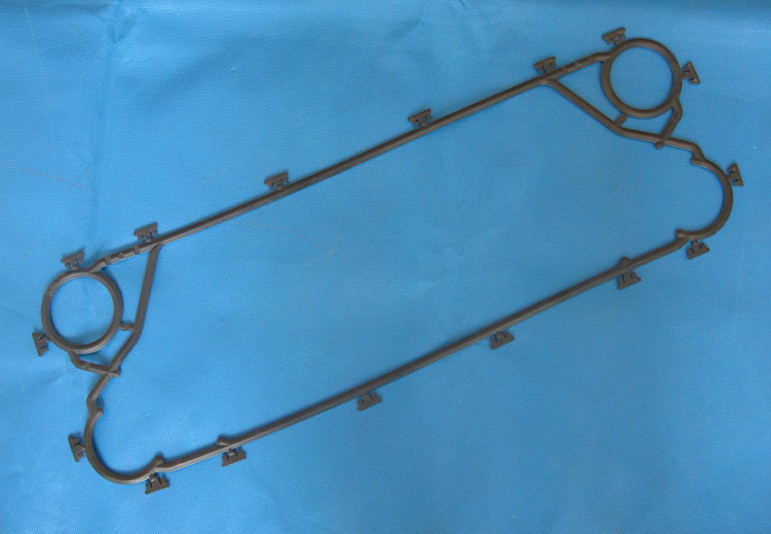

Press the gasket material for comparison table

| Gasket Material | Temperature℃ | Suitable fluid |

| NBR | -15 ~ +135 | Water, sea water, mineral salts, brine |

| EPDM | -25 ~ +180 | Hot water, steam, acid, alkali |

| F26 | -55 ~ +230 | Acid, alkali, fluid |

| FTP | 0 ~ +160 | Concentrated acid, alkali, high temperature oil, steam |

Removable plate heat exchanger notable feature

1.high heat transfer coefficient

As set plate medium flowing in the lower Reynolds number (Re), can form a turbulent flow, and easily generate a smooth plate surface dirt, so a very high heat transfer coefficient. In general the water and the water heat exchanger, the heat exchanger heat transfer coefficient can reach 5000w/m2 above, shell and tube heat exchangers to be 2-4 times higher.

2.high heat recovery

Because high heat transfer coefficient, temperature difference can choose very low, so it is suitable for low energy recovery. In general, the recovery of the plate heat exchanger can be about 90%.

3.flexibility

As plates can be combined into a variety of processes, plate heat exchanger can therefore optimize the design, and the flexibility to adapt to changes in thermal load, simply increase or decrease the number of pieces, not to be replaced framework, will be able to adapt to new changes the process conditions.

4.low retention

Since the flow channel is small, a small retention, so the plate heat exchanger has a good temperature control capability, but also greatly reduce the weight of the equipment. Especially in the heat-sensitive materials handling division, the plate heat exchanger superior.

5.compact

The space occupied by the plate heat exchanger is a variety of a smaller heat exchanger. In the same heat transfer conditions, the area of the plate heat exchanger shell and tube heat exchangers only 1/3-1/4. And when the demolition does not require extra space for maintenance.

6.easy maintenance

Plate is designed to be no dead zone, so that in the field without removing the chemical cleaning can be in most cases, the arrangement of one-way flow of the heat transfer medium can export are mounted to the mounting plate, so that design unnecessary cleaning or repair plates that split pipes, greatly reducing maintenance time.

Sealing principle

The corrugated sheet is adhered gaskets, sealing gasket design dual channel structures with signal holes. When the media, such as from the first seal leaks, holes can escape from the signal, will be able to identify problems early to be resolved, will not cause the two media mix. Gasket according to different media and operating temperature use different types of plastic.

Fixing and sealing:

Snap fixing and sealing gasket functions are separated, so that even when the fixed problem occurs, the spacer can still ensure its sealing function.

Reasonable triage area can:

Uniform velocity, in addition to flow dead zone, thus avoiding the accumulation of dirt and the corrosion, while improving the utilization of plate heat exchanger area.

Two fluids completely reverse flow, greatly improving the efficiency of heat transfer.

The same kind of fluid inlet and outlet pipes in parallel, simplifying installation works.

A single sheet, simplifying maintenance.

| Jiangyin Mingri Machine CO.,LTD | Contactor:Mr Wang | ||

| Add: Fuye Road5#,Huangtang xuxiake Town,Jiangyin City,Jiangsu Province | Mobile:  +86-13606168152 +86-13606168152 |

||

Tel:  +86-510-86538092,+86-510-86530695 +86-510-86538092,+86-510-86530695 |

E-mail:mingrijx@yahoo.com.cn | ||

| Fax:+86-510-86530693 | Web:http://www.mingrimach.com/ |

copyright © Jiangyin MIngRi Machine Co.,Ltd. 2013