Brazed plate heat exchanger notable feature

For the majority of users to save the investment and freight to provide a guarantee

1. compact, easy to install

Using thin films

High insulation factor

Lag less liquid

2. less water consumption

Brazed plate heat exchanger heat transfer efficiency, it only needs the same cooling conditions equivalent shell and tube heat exchanger 1/3 of the cooling water flow.

3. low fouling factor

High turbulence reduces the fouling factor, thereby reducing the number of cleanings.

4. light weight

Only the equivalent of a shell and tube heat exchanger unit 20% to 30%.

5. durable

Can withstand high temperatures (250 degrees) and high pressure (45bar)

Clear corrosion problems

Canceled the gasket

6. high-quality

Over the years of operating experience in the field of heat transfer and precise computer-aided design, Bürkert plate heat exchanger with the domestic same industry leading standards. Our products are widely used in metallurgy, food, light industry, chemical industry, and other fields of refrigeration and HVAC

According to the type of solder, brazed plate heat exchanger can be divided into

|

|

Technical parameters

|

Minimum Operating Temperature

|

-160℃

|

|

Maximum working temperature

|

+225℃

|

|

Minimum working pressure

|

Vacuum

|

|

Maximum working pressure

|

30/15bar

|

|

Test pressure

|

45/63bar

|

|

Single volume

|

0.095L

|

|

Maximum flow water side

|

8m3/h

|

|

Combination plate

|

D,H,X,DM,HM,XM

|

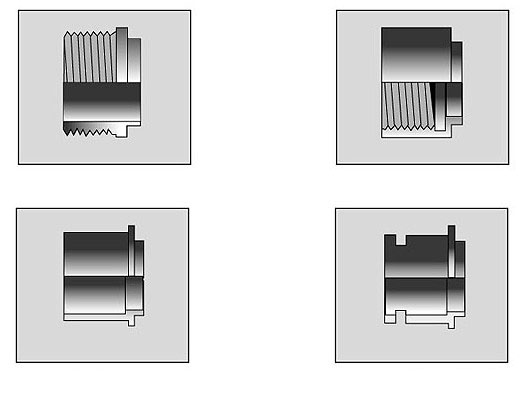

Different forms according to external users, the Company provides the following four different types of interfaces

| Jiangyin Mingri Machine CO.,LTD | Contactor:Mr Wang | ||

| Add: Fuye Road5#,Huangtang xuxiake Town,Jiangyin City,Jiangsu Province | Mobile:  +86-13606168152 +86-13606168152 |

||

Tel:  +86-510-86538092,+86-510-86530695 +86-510-86538092,+86-510-86530695 |

E-mail:mingrijx@yahoo.com.cn | ||

| Fax:+86-510-86530693 | Web:http://www.mingrimach.com/ |

copyright © Jiangyin MIngRi Machine Co.,Ltd. 2013